Power-to-salt systems

For industrial size plants and utility scale projects, a significant optimization of a system’s flexibility and efficiency can be achieved by integrating a power-to-salt system.

Benefits

- Decarbonization of power, heat and steam production

- Optimized efficiency

- System flexibility and grid stability

- Supports sector coupling and electrification

- Security of supply

- Bankable and scalable solution

Green electricity, steam and heat

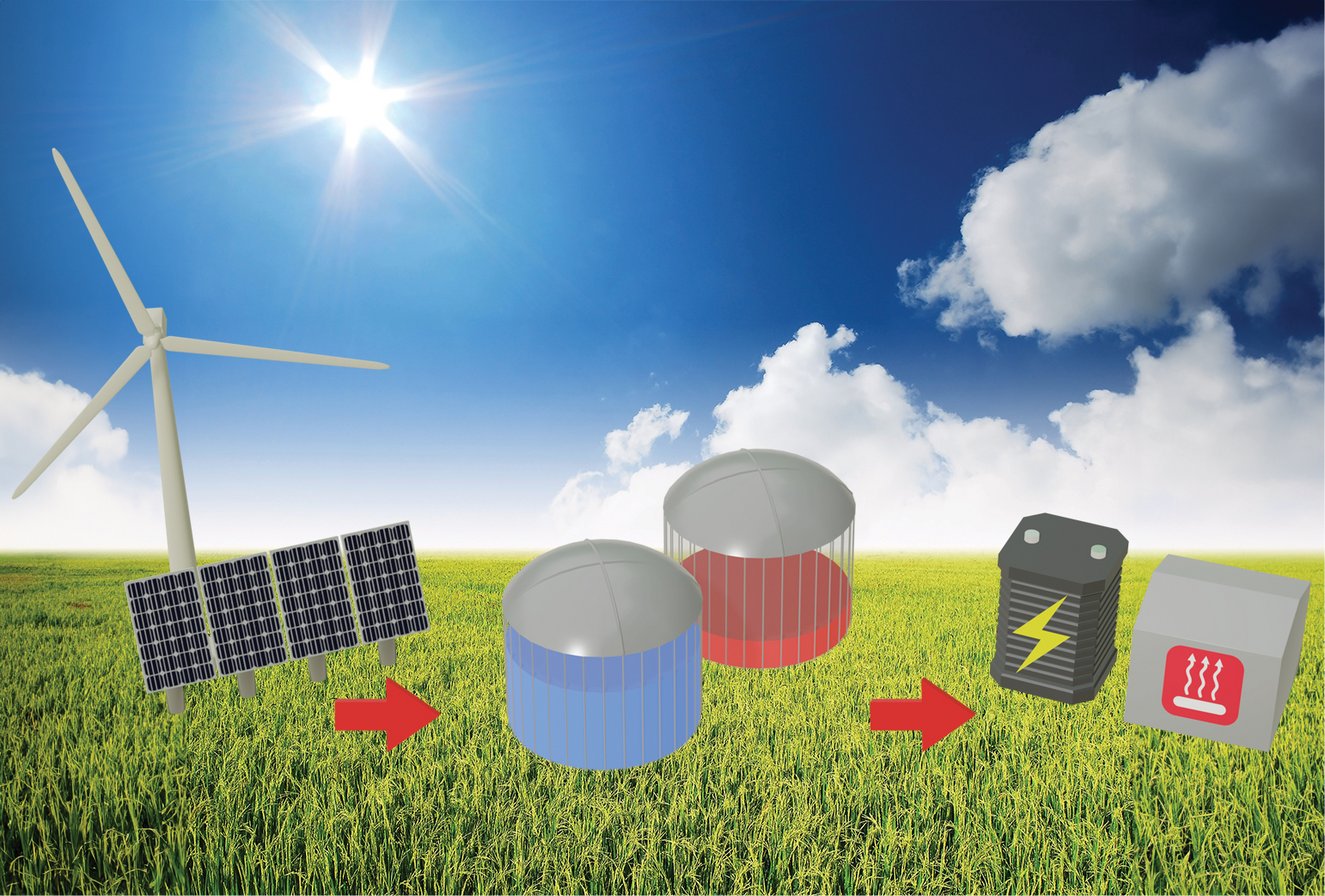

Power-to-salt (PTXSALT) systems utilize the sustainable mass of molten salt as storage medium of high temperature energy in the range of up to 565º C. This can, on demand, enable green power supply which can be used for power production for daily and weekly load shifting in the electricity grid as well as for constant power supply for well-known PTX technologies such as hydrogen and methanol production. Likewise, it can be used to generate high temperature steam for various industrial processes.

High long-term reliability

Electricity from solar PV and wind turbines is stored in a two molten salt tanks. On demand, the energy is converted back to steam, to be used for the production of electricity, steam or heating. The molten salt steam generator is based on the header-coil technology, which is a fundamental building block for reliable long-term thermal storage. It is the only existing heat exchanger type with high long-term reliability and efficiency under cyclical load conditions, which is a critical point of focus for PTXSALT plants.

Want to know more about power-to-salt systems?

Power-to-salt systems

Ensures significant optimization of a system’s flexibility and efficiency for industrial size and utility scale projects.

Carnot battery

Flexible, low-cost and efficient storage solution for balance between supply and demand and security of supply.

Coal conversion

Turning coal fired power plants into renewable energy hubs by means of molten salt thermal energy storages.

WANT TO KNOW MORE? :

Jens Taggart Pelle

Vice President of Technical Sales

Header-coil heat exchangers

Phone: +45 30 80 69 10