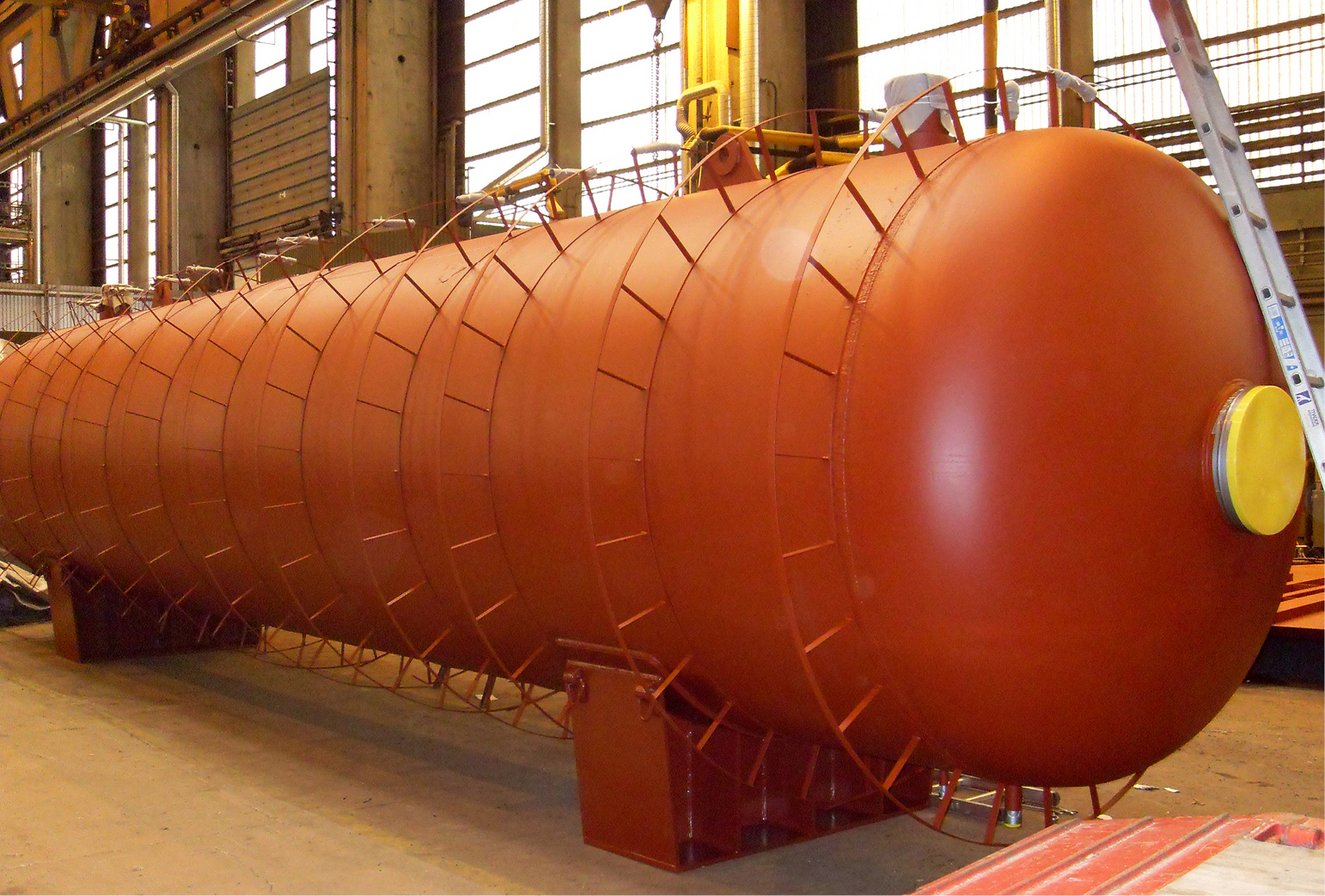

Molten salt steam generators

The molten salt steam generators are developed as shell-and-tube type with Header-Coil equipment

and are designed to meet emerging market expectations for cost-efficient and reliable electricity production.

Benefits

- Customized solutions

- High long-term reliability

- Optimized thermal performance

- Leakage-free design

- Rapid ramp-up and flexible operation

- Natural circulation for optimal and stable operation

- Automatic venting and easy draining

- CAPEX saving on auxiliary equipment

- Lower operation and maintenance costs

Higher availability in moten salt plants

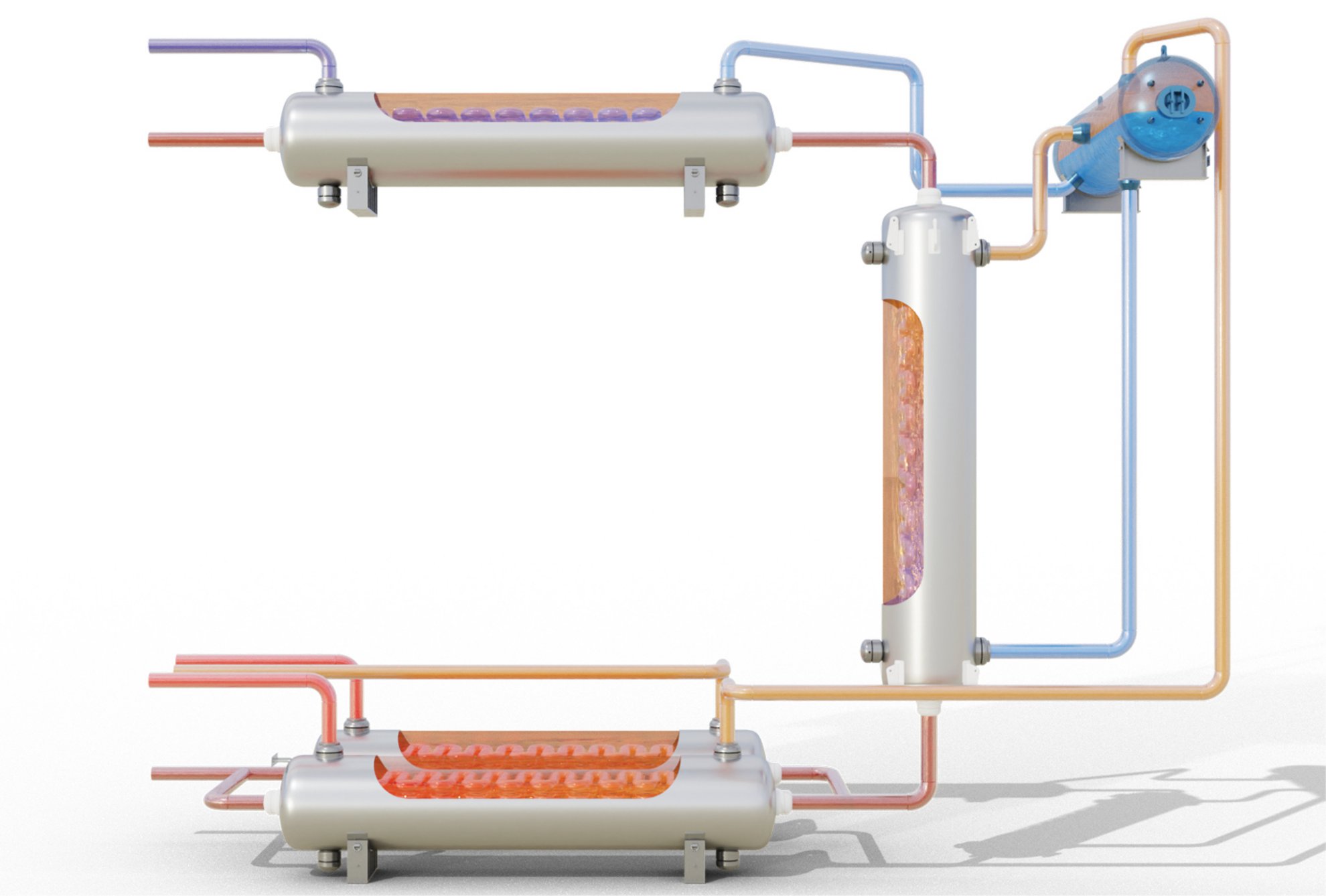

The molten salt steam generation system is developed as shell-and-tube type with header-coil heat exchangers complying with ASME and TEMA standards. The system allows all components to have molten salt on the shell side, while maintaining the option of using natural circulation for optimal and stable operation below 140 bar.

For the evaporators we select a suitable tube material, which can operate with high temperatures sustaining normal blow-down levels during operation. This translates into operational benefits and up to €4 million initial CAPEX saving on auxiliary equipment for the steam generation system designed for a 100MWe reference plant as well as lower operation and maintenance costs for two main reasons:

1. No need for circulation pumps

The natural circulation within the evaporator unit eliminates the use of circulation pumps and the associated initial investment costs associated with it. Furthermore, the electricity consumption and the risk of operational failures are significantly reduced.

2. Reduced amount of venting and drain valves

The elevated layout contributes to automatic venting and achieves easy draining as the header-coil heat exchangers allow the molten salt to flow by gravity alone. Therefore, there is less need for venting and draining valves, enabling the customers to save on auxiliary equipment, which consequently makes operation and maintenance of the plant easier.

Oil-to-salt heat exchangers

Ensures a safe and reliable heat transfer and optimized performance between the hot and cold TES tanks.

Thermal oil steam generators

Provides operational benefits such as fast start-up, leakage-free operation and low maintenance requirements.

Molten salt steam generators

Designed to meet emerging market expectations for cost-efficient and reliable electricity production.

Want to know more?

Jens Taggart Pelle

Vice President of Technical Sales

Header-coil heat exchangers

Phone: +45 30 80 69 10